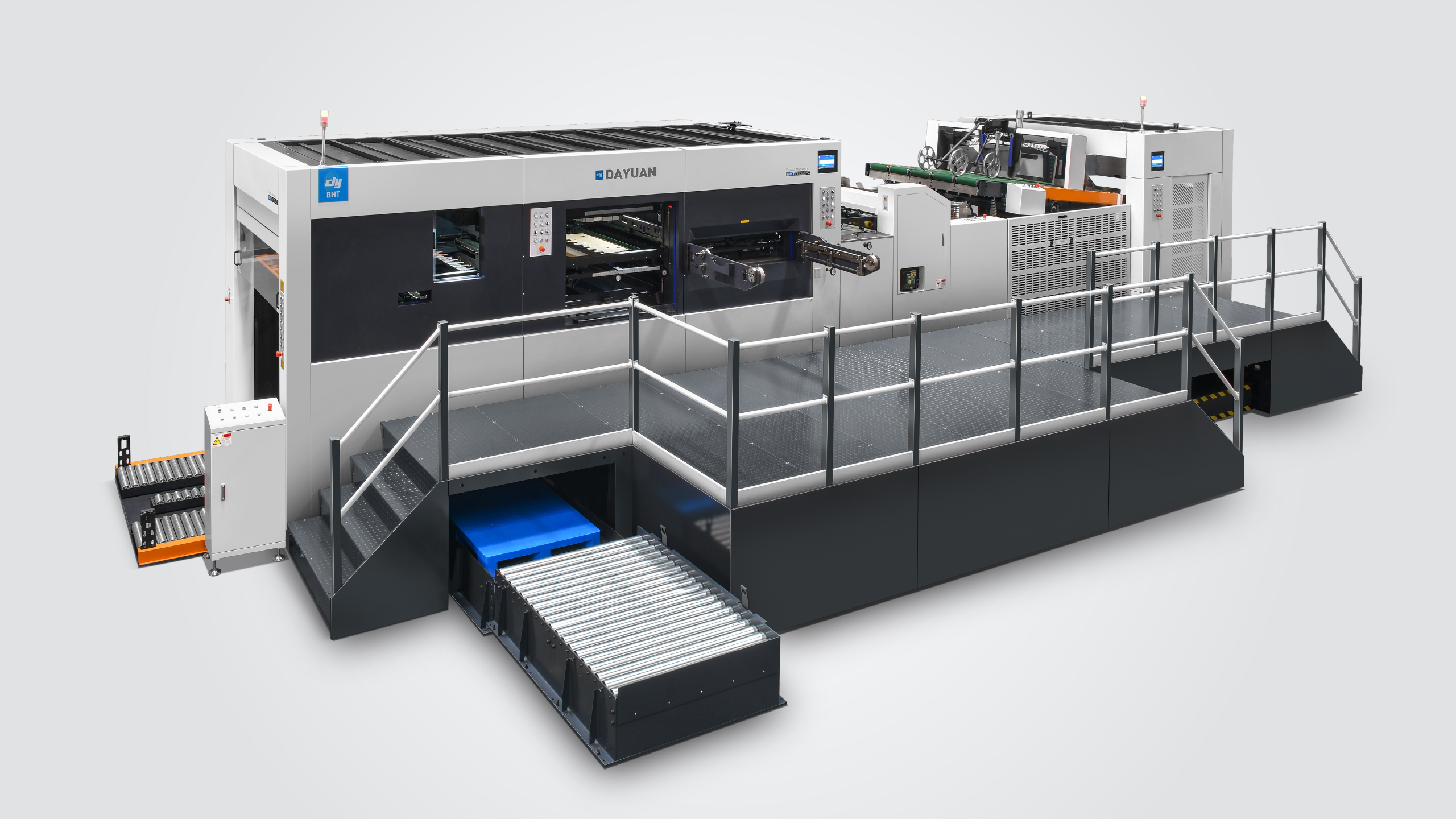

BHT 1500EFC/1650EFC/1900EFC/2100EFC

Automatic Die Cutting & Creasing Machine with Stripping & Auto Pallet Changer (Down Feeder)

Features Introduced

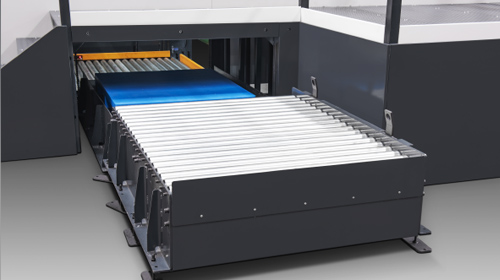

Down Feeder

● Non – stop down suck feeder.

● Pneumatic board for sheet trimming.

● Down suck feeding to protect the printing.

Sheet transmission and alignment section

● Selectable left and right side push lays to ensure accurate alignment.

● Advanced non-stop adjustment of feeding timing, reduce down time.

● Front gauge non-stop back and forth adjustable to accommodate variation in gripper margin.

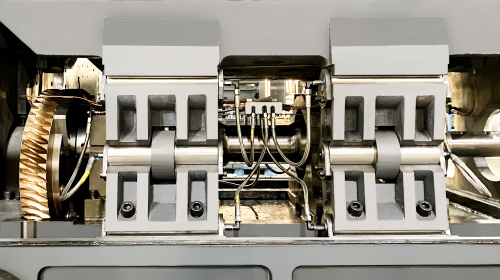

Variable speed worm gear drive device

The system features a unique worm gear crank mechanism driving an toggle-type high-precision flatbed die-cutting lower workstation. With short cutting stroke and large dynamic angle, it enables efficient multi-up high-speed operation.

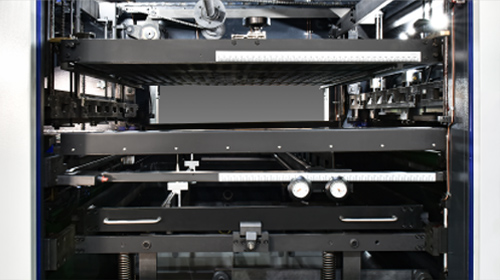

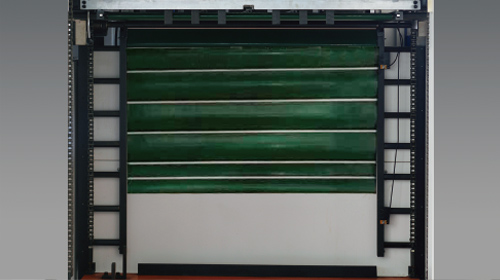

Three layer stripping section

● Stationary middle stripping board, coupled with zero jerk, smooth upper frame motion curve with extra punch at the moment of impact to obtain cleaner waste removal.

● Gripper bar register block at outlets of Stripping Station ensures the accuracy of stripping.

● Center line system for quick stripping tool set up and change over, compatible with centerline.

● Front edge waste removal system removes and transfers waste edge outside the machine via conveyor belt.

Auto non-stop collecting device

Main collecting device and Auto non-stop roll-up type auxiliary collecting device switch automatically without any operation, significantly enhancing productivity.

Auto logistic system