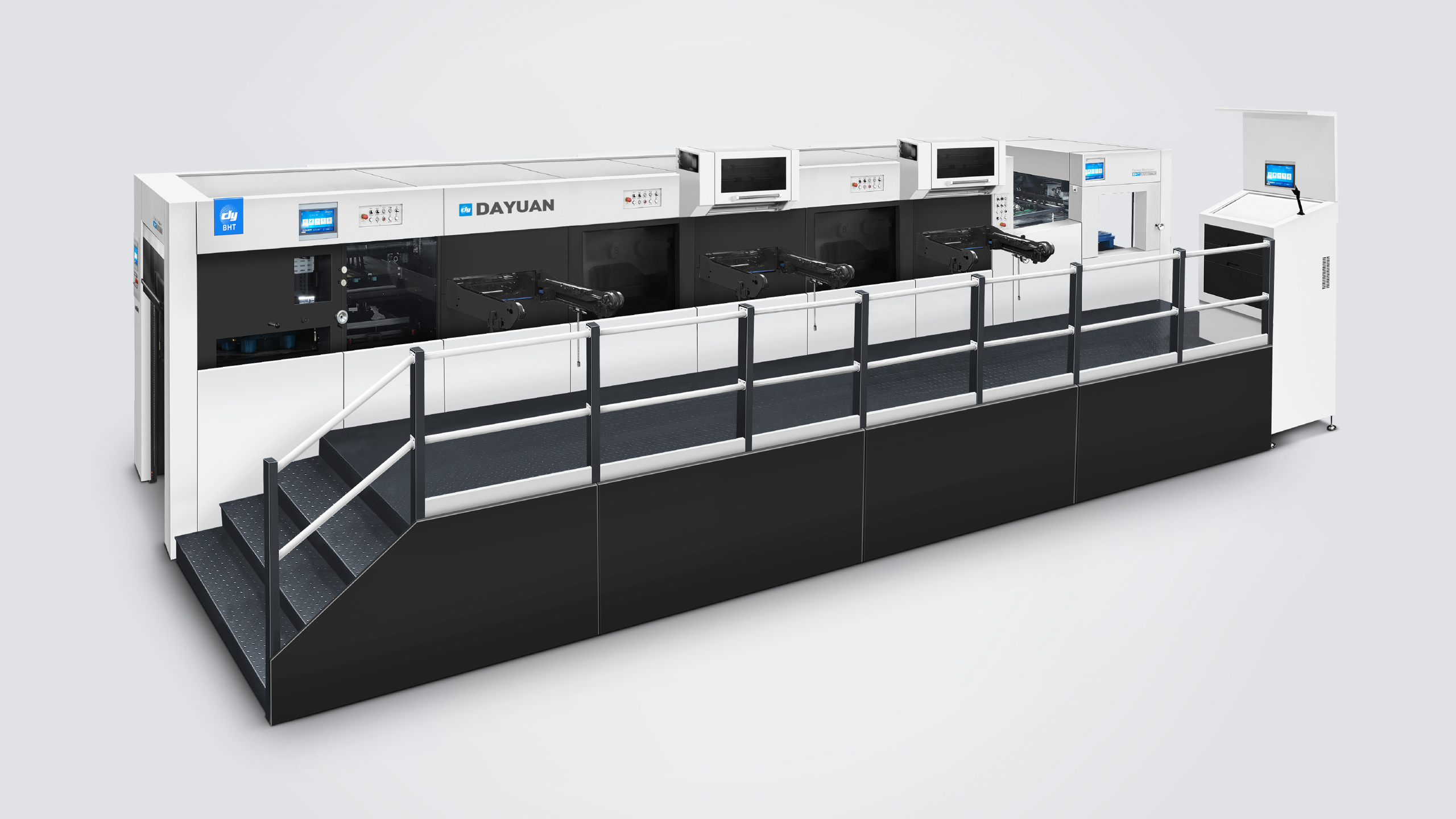

BHT 3S1060TTRC

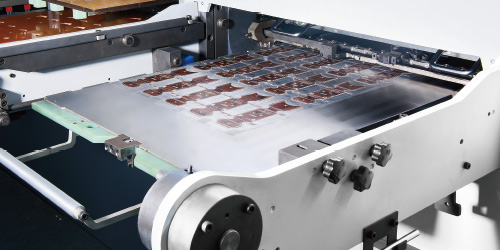

TRIOPRESS Automatic High Speed Duoble Hot Stamping & Die Cutting Machine with Stripping & Heating System

Product Features

The job you can realize in one pass as below:

1. hot stamping+hot stamping+die cutting+stripping

2. hot stamping+deep embossing+die cutting+stripping

3. deep embossing+deep embossing+die cutting+stripping

4. hot stamping+hot stamping+deep embossing

Partial Introduction

Feeder(4 suction and 6 delivery)

The paper feeding unit, designed based on an advanced technology platform, ensures precise, stable, and reliable performance, enabling smooth transportation of various paper types—from 80g thin paper to corrugated cardboard up to 4mm thick.

Ultrasonic double sheet detector

Ultrasonic double sheet detection system with effortless calibration, precise operation, and protection against surface scratches.

Carbon fiber gripper bar

High-tech carbon fiber gripper bar, driven by a large-angle intermittent mechanism, ensures smooth paper feeding with multi-imposition layouts and minimal connection points, delivering high productivity with minimal plate scattering.Safety gripper chain lock automatically secures the gripper drive chain during production stops, malfunctions, or safety device activation, ensuring operator safety.

Servo controlled gripper bar positioning device

Servo control system is adopted for the rear positioning of gripper bar, and the accuracy of each gripper bar can be adjusted by PLC touch screen button to ensure the accuracy of gripper bar, with permanent accuracy of ±0.075mm (Invention Patent).

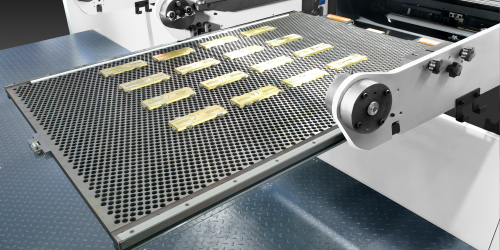

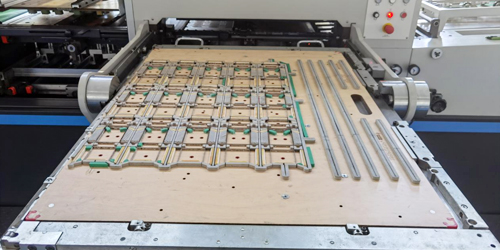

Micro-adjustable honeycomb plate

20-Zone Independent Temperature Control System ensures precise heating of the hot stamping plate, delivering balanced and stable temperature distribution across the entire heating system. Maximum stamping pressure reaches 600 tons.

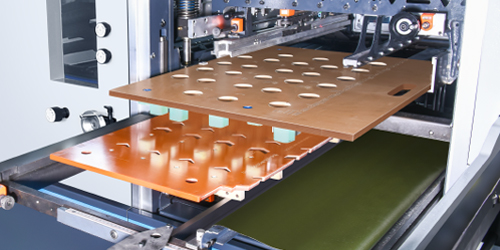

Micro-adjustable die cutting plate

5mm hardened cutting plate or 4+1mm sandwich plate on top of 15mm precision synthetic supporting plate with +/-0.9mm micro adjustment device for quick set up and easy change over.

Micro-adjustable frame with quick locking device

Adopt the center line quick positioning installation device, and the stripping board can quickly installed.

Advanced plate quick locking device

Advanced quick tooling set up system ensures fast plate change over and hence high productivity at stripping stations.

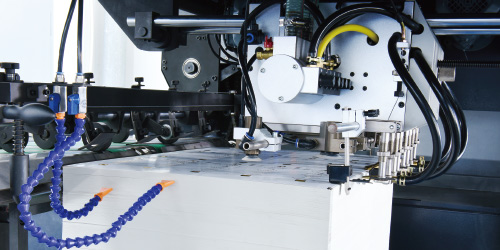

Main unit cooling/lubrication mechanism

Automatic oil pumping circulation cooling device ensures the lubrication of the main machine during long-term high-speed operation and maintains the normal temperature of the lubricating oil of the main machine.

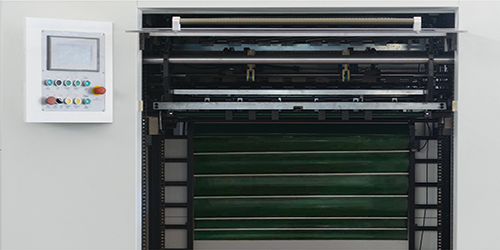

Non-stop roll-up curtain type paper delivery device

Main collecting device and Auto non-stop roll-up type auxiliary collecting device switch automatically without any operation, significantly enhancing productivity.

Germany vaccum pump

Blow-suction dual-purpose vacuum pump of German Becker brand.

Auto lubrication system

The whole machine adopts a centralized automatic oil supply system to ensure that the transmission parts are not short of oil.

Configurations

| Conveying Unit | BHT-3S1060TTRC |

| 01. Non-stop high-speed paper feeding section | 〇 |

| 02. Fish-scale powerful paper suction feeder head with 4 suction and 6 delivery. The suction head can be adjust to various suction angles according to the deformation of the paper | 〇 |

| 03. Adjustable suction blower, suction head and air separation valve processed with ultra-hard alloy | 〇 |

| 04. Triple feeder head anti-collision device | 〇 |

| 05. Horizontal paper separation blower | 〇 |

| 06. The main and auxiliary stacking tables alternate without stopping, and the feeder operates without stopping | 〇 |

| 07. Electrical left/right fine-tuning device for the main feed pile | 〇 |

| 08. The pre-stacking device is equipped with rails so that the operator can accurately and conveniently send the stack of paper into the feeder | 〇 |

| 09. The paper alignment adjustment device can manually adjust the distance before the paper reaches the gauge without stopping the machine | 〇 |

| 10. Large inclined paper table, suitable for high-speed conveying of thin paper and curved paper | 〇 |

| 11. Slowdown mechanism for sheet feeding at the front gauge | 〇 |

| 12. Ultrasonic double sheet detection system with effortless calibration, precise operation, and protection against surface scratches | 〇 |

| 13. Four front gauges can be adjusted individually | 〇 |

| 14. Paper pressing device, more smoothly send the curved paper to the front gauge | 〇 |

| 15. Push-pull dual-purpose side gauges, one set for the operation side and one set for the transmission side. Side gauges can be adjusted between push-pull gauges to meet different paper requirements | 〇 |

| 16. Photoelectric detection of side gauge and front gauge | 〇 |

| 17. Imported paper feeding belts and stainless steel conveying plates | 〇 |

| 18. Pneumatic lifting device for paper feeding frame | 〇 |

| 19. PLC and electronic cam control the timing of the whole machine | 〇 |

| 20. Blow-suction dual-purpose vacuum pump of German Becker brand | 〇 |

| 21. If the paper is not in place, it can force the gripper open and close | 〇 |

| Die-cutting Unit | |

| 01. The entire machine casting is made of QT-700-2 nodular cast iron | 〇 |

| 02. Imported worm gear, worm gear and 40cr crankshaft | 〇 |

| 03. A complete set of high-tech carbon fiber gripper bars and positioning structure, fine steel small gripper teeth and supporting gripper plates. The gripper bars adopt an adjustable gripper bar structure | 〇 |

| 04. Imported main drive chain | 〇 |

| 05. Servo control system is adopted for the rear positioning of gripper bar, and the accuracy of each gripper bar can be adjusted by PLC touch screen button to ensure the accuracy of gripper bar, with permanent accuracy of ±0.075mm (Invention Patent) | 〇 |

| 06. Imported intermittent splitter | 〇 |

| 07. Imported synchronous belt and pulley drive | 〇 |

| 08. Imported torque limiting overload protector | 〇 |

| 09. Imported pneumatic clutch brake device | 〇 |

| 10. Pressure regulating device, which can realize accurate control of pressure through PLC touch screen buttons | 〇 |

| 11. Die-cutting pressure is measured directly and accurately by deformation measuring device and displayed on the human-machine interface | 〇 |

| 12. Die-cutting base plate and die mould rotary device | 〇 |

| 13. The 15mm die-cut steel backing plate is equipped with a 5mm combined lower backing plate center positioning structure +/-0.9mm vertical and horizontal fine-tuning device, which makes plate changing fast and simple, reducing the time for plate replenishment | 〇 |

| 14. The connection between the die cutting plate and the chase adopts the form of grasping snail and screws, adopt central positioning system, which is fast and accurate | 〇 |

| 15. The die-cutting frame has a fine-tuning function to facilitate the adjustment of the frame | 〇 |

| 16. The die-cutting chase and the lower mat are locked by the Japan SMC gas regulator, which can prevent improper locking of the upper frame caused by human error during installation | 〇 |

| 17. The main motor utilizes servo motor transmission | 〇 |

| 18. Japan SMC air pressure detection device, low air pressure alarm | 〇 |

| 19. Equipped with an air storage tank to ensure the stability of the air pressure of the whole machine | 〇 |

| 20. The whole machine adopts a centralized automatic oil supply system to ensure that the transmission parts are not short of oil | 〇 |

| 21. Automatic oil pumping circulation cooling device ensures the lubrication of the main machine during long-term high-speed operation and maintains the normal temperature of the lubricating oil of the main machine | 〇 |

| Stripping Unit(Three frames and four sides) | |

| 01. Upper waste transmission mechanism | 〇 |

| 02. Users can choose whether to use the stripping function by lifting upper stripping frame | 〇 |

| 03. The upper stripping frame adopts pneumatic quick lock device | 〇 |

| 04. Pull-out drive mechanism with quick locking function for intermediate negative stripping frame | 〇 |

| 05. The installation of the middle stripping board adopts the center line quick positioning installation method, and the stripping board can be quickly installed. The upper and lower frames operate while the middle frame remains stationaryso there are fewer connection points, and the plate is not prone to coming apart | 〇 |

| 06. Center positioning is adopted for the lower stripping frame | 〇 |

| 07. Lower stripping transmission mechanism | 〇 |

| 08. High efficiency and smooth CAM movement curve drives large moving angle stripping and full stripping tools to ensure stripping at high speed | 〇 |

| 09. Stripping frame has micro-adjustment device with digital display | 〇 |

| 10. Stripping gripper bar positioning device | 〇 |

| 11. Funnel type waste collection device | 〇 |

| 12. The gripper stripping device can automatically convey gripper waste edges out of the machine and, with the stripping slideway, they can automatically slide into the main stripping channel | 〇 |

| Delivery Unit | |

| 01. Roll-up curtain type auxiliary paper delivery device, can realize non-stop paper delivery | 〇 |

| 02. Adjustable mechanical paper delivery brush press mechanism to help gripper bar discharge and stack paper | 〇 |

| 03. Paper delivery alignment device | 〇 |

| 04. Photoelectric detection of upper and lower limit switches can effectively prevent the paper stacking table from excessive paper pile stacking and paper curling up | 〇 |

| 05. The delivery section can control the machine through a 7” touch screen | 〇 |

| 06. The two-way auxiliary air blowing for paper delivery and the manual sampling mechanism make the operation convenient | 〇 |

| 07. Spring chain adjustment device: Adjusting the tension of spring chain can reduce the inertia impact during the steerings of the gripper bar, and maintain the balanced tension of the chain | 〇 |

| Electrical Unit | |

| 01. Self-developed PLC control system(Invention Patent) | 〇 |

| 02. The die-cutting unit and the delivery unit adopt 10.4-inch and 7-inch Germany Siemens touch screens | 〇 |

| 03. The machine adopts Germany Moeller brand relays, AC contactors, air switches and buttons, to ensure the stability and reliability of electrical parts | 〇 |

| 04. The machine adopts Japanese Omron brand photoelectric switch, optical fiber, encoder and sensor, to ensure the accuracy and stability of electrical detection of each part of the action | 〇 |

| Hot Stamping Control System | |

| 01. Independent research and development of AC801 hot stamping control system, with accurate operation accuracy and fast speed, which can realize high-speed intelligent skip operation with large-format electrochemical aluminum foil (Invention Patent) | 〇 |

| 02. Three vertical and two horizontal independent foil feeding system ensures stable and accurate anodized aluminum conveying at high speed, reliable tension control, and small stretching of aluminum foil | 〇 |

| 03. Three-vertical large-format dual-axis foil rewinding device (Invention Patent) | 〇 |

| 04. Three vertical outer intelligent foil rewinding cabinet device | 〇 |

| 05. The three-vertical foil feeding frame adopts a push-pull device, which is convenient for pulling out the foil feeding frame from the machine to replace the aluminum foil, which is easy and safe to operate | 〇 |

| 06. Hot stamping servo motor adopts direct-connected foil feeding shaft device with high precision | 〇 |

| 07. Equipped with a foil broken detection system to prevent hot stamping waste caused by accidental breakage of foil and improve the yield of hot stamping products | 〇 |

| 08. The 20-temperature zone independent control system can effectively control the heating temperature of the stamping plate, ensuring that the temperature control of the entire heating system is more balanced and stable | 〇 |

| 09. Device for the quick conversion between the stripping and hot stamping functions | 〇 |

| 10. Equipped with foil separation blowing device in vertical and horizontal direction, suitable for large-area stamping | 〇 |

| 11. If the length of foil is shorter than the set parameters, an alarm will be triggered, and the computerized foil monitoring system will display the remaining and used foil length | 〇 |

| 12. 14″ touchscreen display at the hot stamping station | 〇 |

| 13. Holographic anti-counterfeiting foil rack device, quick operation, safe alignment and replacement, easy installation, ensuring accurate and stable holographic hot stamping accuracy (special for holographic hot stamping, optional) | △ |

Note: This allocation sheet is for reference only, the formal allocation sheet is subject to the contract. Standard configuration: 〇; Optional: △

Main Technical Parameter

| Model | BHT-3S1060TTRC |

| Function | 1. hot stamping+hot stamping+die cutting+stripping 2. hot stamping+deep embossing+die cutting+stripping 3. deep embossing+deep embossing+die cutting+stripping 4. hot stamping+hot stamping+deep embossing |

| Max. Sheet Size | 1060×760mm |

| Min. Sheet Size | 400×350mm |

| Max. Cutting Size | 1060×745mm |

| Max. Hot Stamping Size | 1060×740mm |

| Max. Embossing Size | 1060×740mm |

| Min. Gripper Margin | 9-17mm |

| Min. Width of Cuts | 10-18mm |

| Inner Chase Size | 1080×790mm |

| Stock Range | Cardboard: 80-2000g/m², 0.1-2mm Corrugated board: ≤4mm |

| Die Cutting Accuracy | ≤±0.075mm |

| Stamping Accuracy | ≤±0.1mm |

| Embossing Accuracy | ≤±0.075mm |

| Max. Die Cutting Force | Press1: 600T, Press2: 600T, Press3: 600T |

| Max. Working Speed | 6200s/h |

| Max. Feeder Pile Height | 1800mm(With pallet) |

| Max. Pile Height at Feeder-Non-stop Mode | 1520mm(With pallet) |

| Max. Delivery Pile Height | 1580mm(With pallet) |

| Max. Gold Foil Diameter | Φ250mm Longitudinal, Φ200mm Transversal |

| Electric-heated System | 20 Heating zones, 40-180℃ Adjustable |

| Foil Width | 20-1060mm |

| Press 1 System | 3 Longitudinal + 2 Transversal 4 Longitudinal + 2 Transversal (Optional) 5 Longitudinal + 2 Transversal (Optional) 6 Longitudinal + 2 Transversal (Optional) |

| Press 2 System | 3 Longitudinal + 2 Transversal 4 Longitudinal + 2 Transversal (Optional) 5 Longitudinal + 2 Transversal (Optional) 6 Longitudinal + 2 Transversal (Optional) |

| Press 3 System | Equipped with electric heating system+Stripping |

| Full Load Wattage | 165KW |

| Air Requirement | Pressure: 0.6-0.7Mpa, Flow: ≥1m3/min |

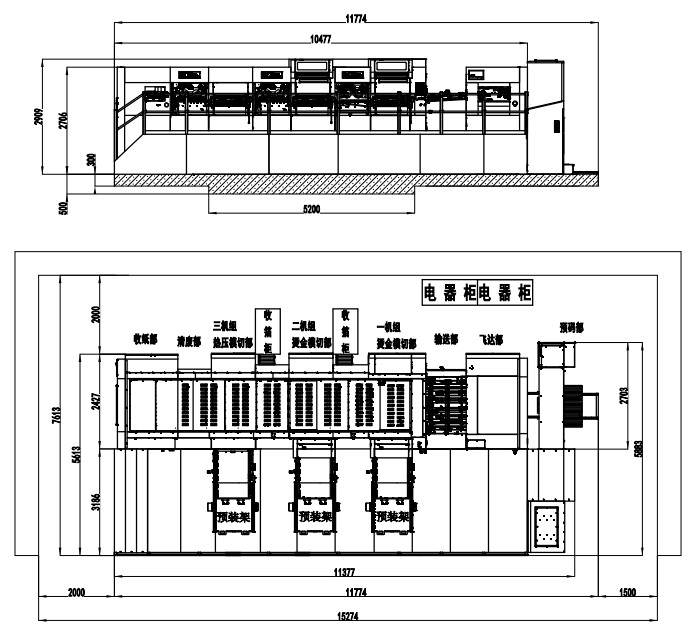

| 11700×5608×2900mm | |

| Net Weight of Machine | 62T |

| Machine Dimensions (Including Die Preloader) | 11774×7613×2909mm(L×W×H) (L: paper prepared track included, W: platform included) |

Drawing