BHT 1500EFC/1650EFC/1900EFC/2100EFC

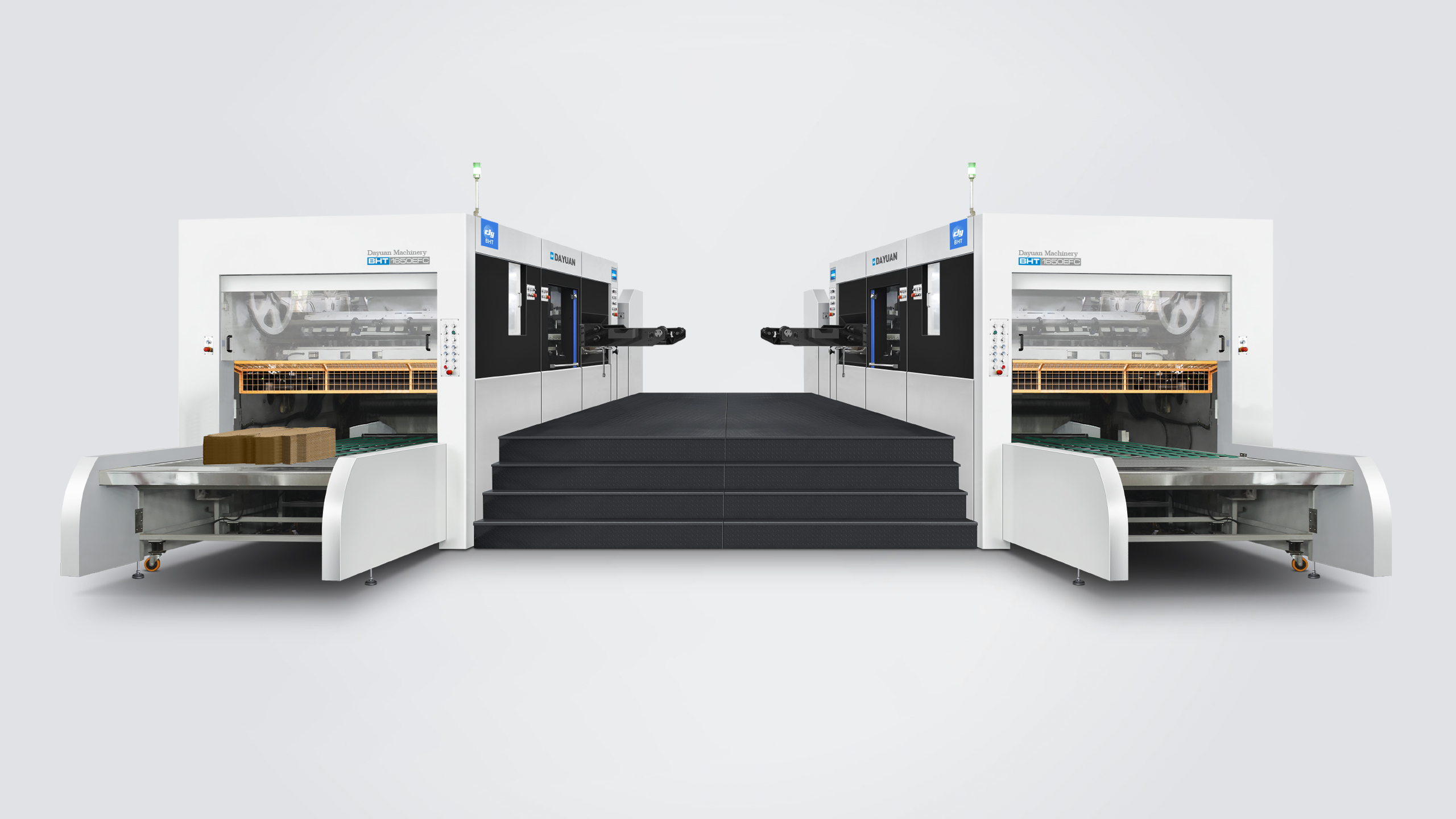

Mirror Machines Dual Diecutter Working Station(Down Feeder)

THE ADVANTAGE OF MIRROR MACHINES DUAL DIECUT TER WORKING STATION

Two flat die cutting machine operation relatively, and make sure the feeding and collecting is homodromous.

Two die-cutting machine Shared the same foot pedals, knife version, stripping, waste clearance version, and all the plate and frame, and even the same plate andframe the function of the switchboard.

Two die cutting machine per shift just one captain, reduce the manpower cost. At the same time, the layout of the two die cutting machinewas face to face, to ensure the whole assignment in a pilot’s visual monitoring range, convenient and when a pilot-in-command discoversthat the anomalies, troubleshooting, improve the yield.

The same frame switchboard and the same plate frame can be used for the matching and installation of the double-unit combined die cutting machine, and the plate frame can be interchanged and installed freely.

The central positioning system of the mobile phone is the same, all molds can be Shared.

Positive and negative (left and right) hand double unit die cutting machine, which can save the machine floor space, is conducive to the enterprise space planning, and the investment efficiency is higher.

Area Saving

| 2 Regular Machines Floor Space | Mirror Machines Floor Space | Total Space Saved | |

| With Chase Loader | 197.3m² | 148.5m² | 48.8m² |

| Without Chase Loade | 172.2m² | 142.8m² | 27.4m² |

Because the same foot pedal is shared, the intermediate channel (at least 2×10 meters) when the two machines are placed separately, can save 2×10=20m2 of plant occupation area.

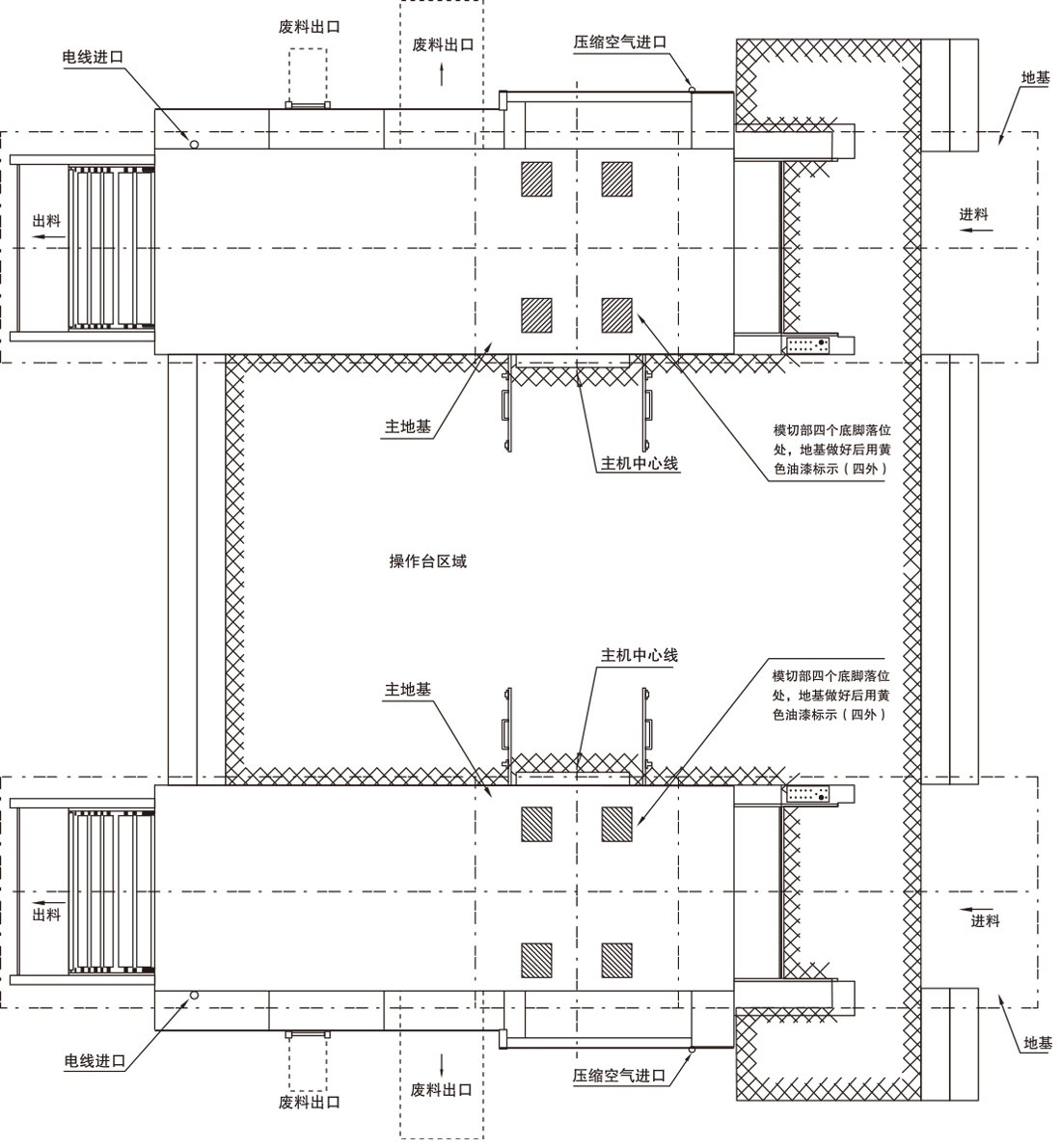

Drawing