MHC 1300EF/1350EF/1500EF/1650EF/1900EF

Automatic Die Cutting Machine (Down Feeder)

Features Introduction

Down Feeder

● Non – stop down suck feeder.

● Pneumatic board for sheet trimming.

● Down suck feeding to protect the printing.

Sheet transmission and alignment section

● Selectable left and right side push lays to ensure accurate alignment.

● Advanced non-stop adjustment of feeding timing, reduce down time.

● Front gauge non-stop back and forth adjustable to accommodate variation in gripper margin.

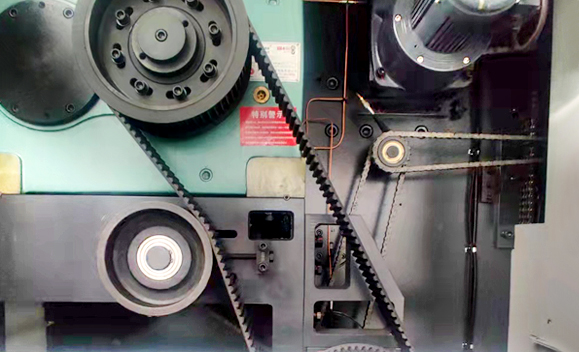

Timing belt drive, Intermittent mechanism

High-precision imported intermittent splitter, capable of maintaining high positioning accuracy even after long-term use.

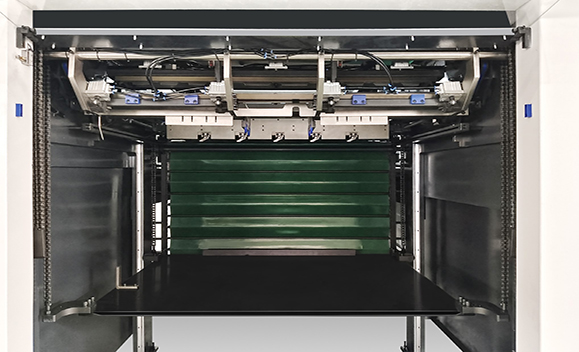

Non-stop roll-up curtain type paper delivery device

Roll-up curtain type auxiliary paper collection rack, which can realize non-stop paper collection. Delivery unit is also equipped with two-way auxiliary blower for paper collecting, with manual sampling mechanism which is easy to operate.

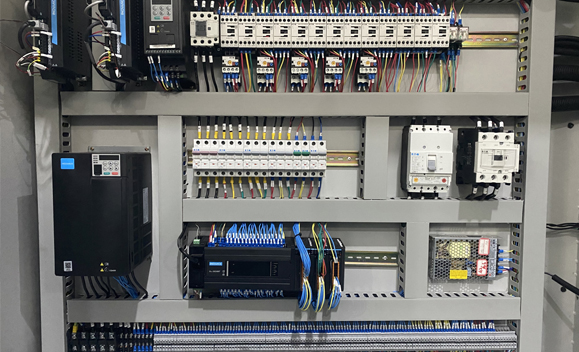

Electrical unit

Adopts electrical components of world famous brands(MOELLER\OMRON) for better performance and in time and local after-sale-service and maintenance.

Germany vaccum pump

Blow-suction dual-purpose vacuum pump of German Becker brand.

Auto lubrication system

The whole machine adopts a centralized automatic oil supply system to ensure that the transmission parts are not short of oil.

Configurations

| Conveying Unit | MHC-1300EF/1350EF/1500EF/1650EF/1900EF |

| 01. High precision bottom suction paper feeder with non-stop suction nozzle at the bottom, uses vacuum adsorption mechanism to send corrugated board into the paper pressing roller, effectively avoiding sheet scratches during feeding | 〇 |

| 02. Electric side pushing baffles and pneumatic side pushing baffle (right sides) | 〇 |

| 03. Electrically controlled paper feed roller | 〇 |

| 04. Paper Presser and front gauge, double sheet detecter respond accurately | 〇 |

| 05. Front hook adjustment device, paper bending up and down can be adjusted | 〇 |

| 06. Non-stop adjusting device for feeding step | 〇 |

| 07. The fine-tuning device for the front baffle’s front and rear positions can be finely adjusted according to the gripper margin size | 〇 |

| 08. Right and left side positioning push gauge to ensure precise side positioning of the board | 〇 |

| 09. Blow-suction dual-purpose vacuum pump of German Becker brand | 〇 |

| Die-cutting Unit | |

| 01. The entire machine casting is made of QT-700-2 nodular cast iron | 〇 |

| 02. Imported worm gear, worm gear and 40cr crankshaft | 〇 |

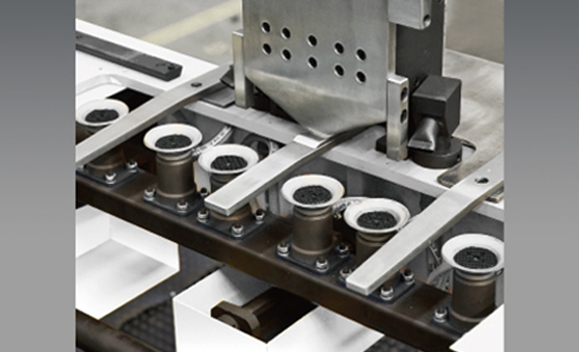

| 03. A complete set of imported anodized aluminum alloy gripper bars and positioning structure, fine steel gripper teeth and supporting gripper plates. The gripper bars adopt an adjustable gripper bar structure | 〇 |

| 04. Imported main drive chain | 〇 |

| 05. Imported intermittent splitter | 〇 |

| 06. Imported synchronous belt and pulley drive | 〇 |

| 07. Imported pneumatic clutch brake device | 〇 |

| 08. Pressure regulating device, which can realize accurate control of pressure through PLC touch screen buttons | 〇 |

| 09. Die-cutting pressure is measured directly and accurately by deformation measuring device and displayed on the human-machine interface | 〇 |

| 10. Die-cutting base plate and die mould rotary device | 〇 |

| 11. The connection between the die cutting plate and the chase adopts the form of grasping snail and screws, adopt central positioning system, which is fast and accurate | 〇 |

| 12. The die-cutting chase and the lower mat are locked by the Japan SMC gas regulator, which can prevent improper locking of the upper frame caused by human error during installation | 〇 |

| 13. Japan SMC air pressure detection device, low air pressure alarm | 〇 |

| 14. Equipped with an air storage tank to ensure the stability of the air pressure of the whole machine | 〇 |

| 15. The whole machine adopts a centralized automatic oil supply system to ensure that the transmission parts are not short of oil | 〇 |

| Delivery Unit | |

| 01. Roll-up curtain type auxiliary paper delivery device, can realize non-stop paper delivery | 〇 |

| 02. High pile stacking table adopts lifting device, paper delivery structure can pull the whole pile of paper out of the machine.(Special for high pile stacking delivery) | 〇 |

| 03. Paper delivery alignment device | 〇 |

| 04. Photoelectric detection of upper and lower limit switches can effectively prevent the paper stacking table from excessive paper pile stacking and paper curling up | 〇 |

| 05. Spring chain adjustment device: Adjusting the tension of spring chain can reduce the inertia impact during the steerings of the gripper bar, and maintain the balanced tension of the chain | 〇 |

| Electrical Parts | |

| 01. Self-developed PLC control system(Invention Patent) | 〇 |

| 02. The die-cutting unit adopts 10.4-inch touch display screens | 〇 |

| 03. The machine adopts Germany Moeller brand relays, AC contactors, air switches and buttons, to ensure the stability and reliability of electrical parts | 〇 |

| 04. The machine adopts Japanese Omron brand photoelectric switch, optical fiber, encoder and sensor, to ensure the accuracy and stability of electrical detection of each part of the action | 〇 |

Note: This allocation sheet is for reference only, the formal allocation sheet is subject to the contract. Standard configuration: 〇; Optional: △

Main Technical Parameter

| Model | MHC-1300EF | MHC-1350EF | MHC-1500EF | MHC-1650EF | MHC-1900EF |

| Max. Sheet Size | 1290×940mm | 1350×1100mm | 1500×1100mm | 1650×1200mm | 1900×1400mm |

| Min. Sheet Size | 470×450mm | 470×450mm | 470×450mm | 550×500mm | 650×550mm |

| Max. Cutting Size | 1280×920mm | 1330×1080mm | 1480×1080mm | 1620×1180mm | 1870×1380mm |

| Minimum Gripper Margin | 9-17mm | 9-17mm | 9-17mm | 9-17mm | 9-17mm |

| Cutting Rule Height | 23.8mm | 23.8mm | 23.8mm | 23.8mm | 23.8mm |

| Inner Chase Size | 1310×950mm | 1390×1120mm | 1510×1120mm | 1682×1220mm | 1912×1420mm |

| Stock Range | Corrugated board: ≤8.5mm, E, B, C, A and AB corrugated paper | Corrugated board: ≤8.5mm, E, B, C, A and AB corrugated paper | Corrugated board: ≤8.5mm, E, B, C, A and AB corrugated paper | Corrugated board: ≤8.5mm, E, B, C, A and AB corrugated paper | Corrugated board: ≤8.5mm, E, B, C, A and AB corrugated paper |

| Die Cutting Accuracy | ≤±0.15mm | ≤±0.15mm | ≤±0.15mm | ≤±0.2mm | ≤±0.2mm |

| Max. Die Cutting Force | 400T | 400T | 400T | 400T | 450T |

| Max. Working Speed | 5500s/h | 5500s/h | 5500s/h | 4500s/h | 4000s/h |

| Max. Delivery Pile Height | 1400mm (With pallet) | 1400mm (With pallet) | 1400mm (With pallet) | 1400mm (With pallet) | 1500mm (With pallet) |

| Min. Motor Power | 11KW | 15KW | 15KW | 18.5KW | 18.5KW |

| Full Load Wattage | 20KW | 24KW | 24KW | 28KW | 28KW |

| Air Requirement | Pressure: 0.6-0.7Mpa, Flow: ≥0.37m3/min | Pressure: 0.6-0.7Mpa, Flow: ≥0.37m3/min | Pressure: 0.6-0.7Mpa, Flow: ≥0.37m3/min | Pressure: 0.6-0.7Mpa, Flow: ≥0.75m3/min | Pressure: 0.6-0.7Mpa, Flow: ≥0.75m3/min |

| Net Weight of Machine | 20T | 22T | 23T | 25T | 31T |

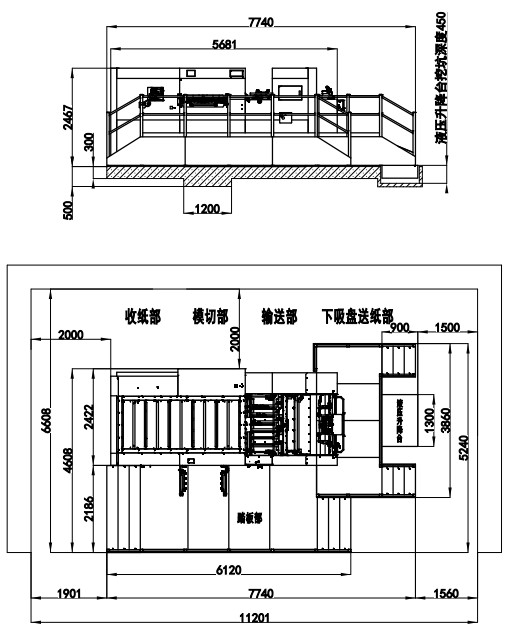

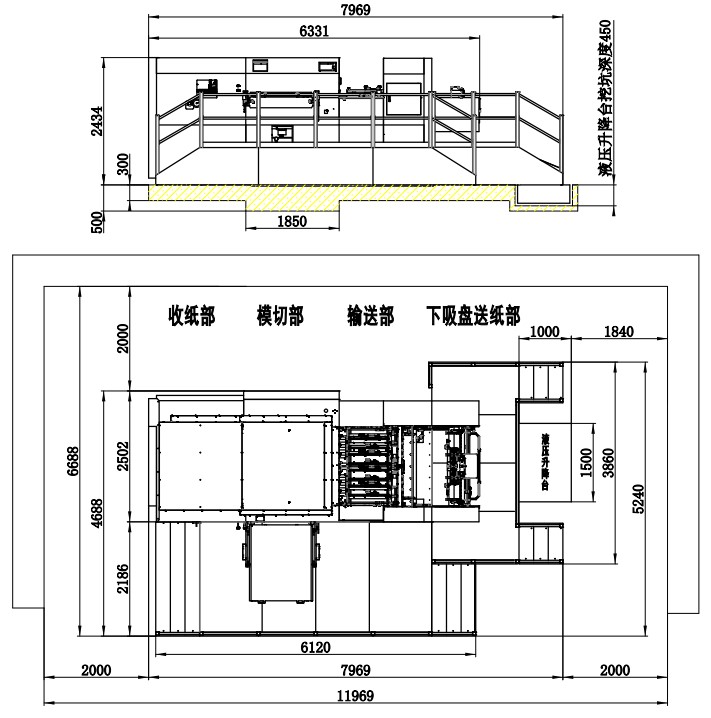

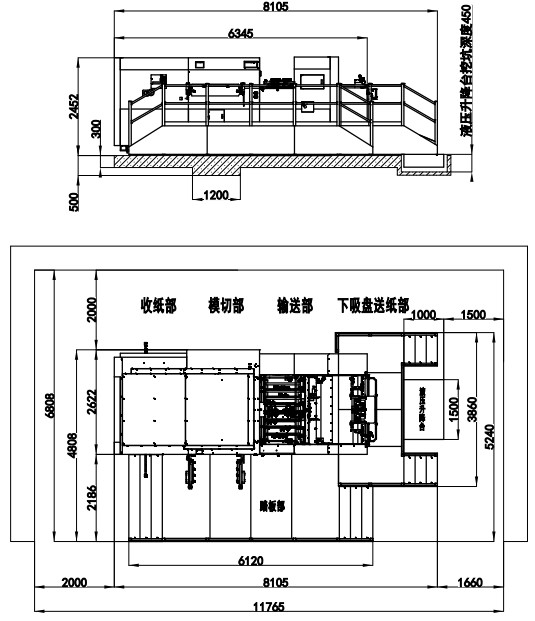

| Machine Dimension | 7740×5240×2467mm (L: paper prepared track included, W: platform included) | 7969×5240×2434mm (L: paper prepared track included, W: platform included) | 8105×5240×2452mm (L: paper prepared track included, W: platform included) | 8322×5580×2582mm (L: paper prepared track included, W: platform included) | 8900×6260×2525mm(L: paper prepared track included, W: platform included) |

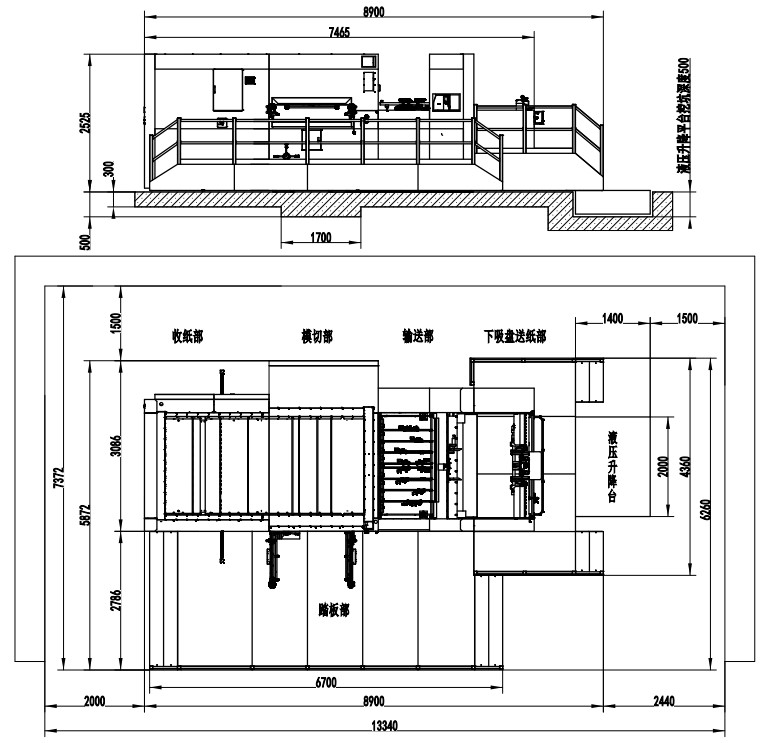

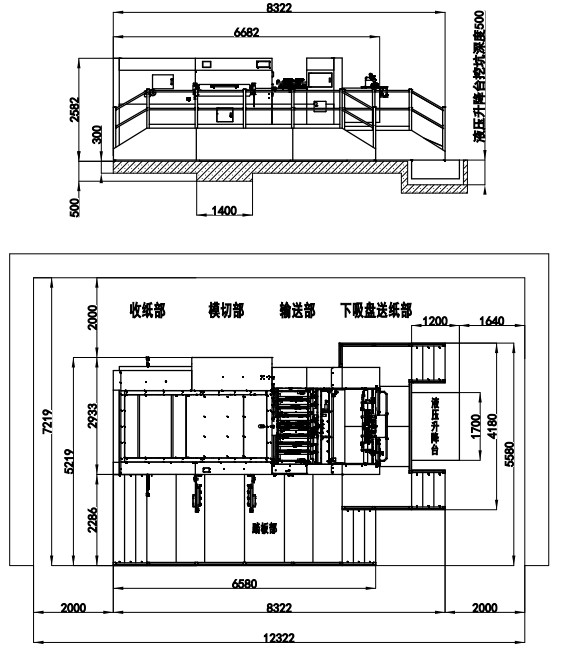

Drawing

MHC-1300EF

MHC-1350EF

MHC-1500EF

MHC-1650EF

MHC-1900EF