PRODUCT

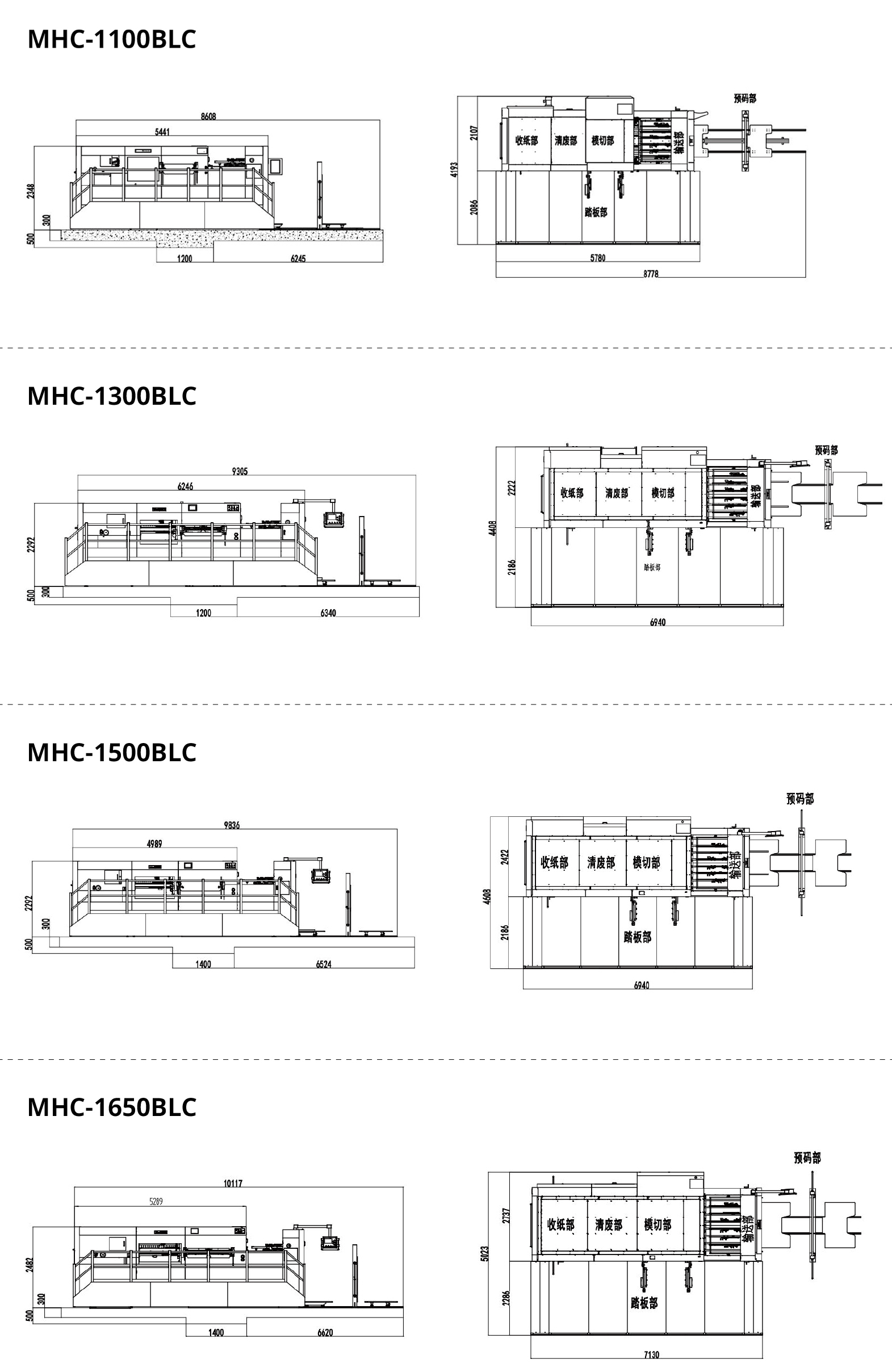

MHC 1100BLC/1300BLC/1500BLC/1650BLC

Semi-automatic Die Cutting Machine With Stripping & Feeding Table

Features Introduction

MHC series Semi-automatic Die Cutting Machine is equipped with front conveyor delivery mechanism. The two groups of pressing wheels and two times positioning function will make the products more flat, and improve the accuracy and speed. The machine’s development is combined with advantages of similar products in domestic and over seas, is special equipment for packing products such as cartons and paper boxes. Gripper bars with high intensity are applicable to all kinds of cardboard, paperboard and corrugated paper. Frontal, back and side registration mechanism ensures great precision of die-cutting. Other parts are adopted such as intermittent mechanism with high precision, air clutch, pneumatic locking mechanism, programmable controller and man-machine interface. The interface can display various digital information of machine such as working speed, amount of paper processed, total running time, etc. It is easy to eliminate troubles according to the display of trouble shooting. Transducer is adopted to control the main motor in achieving step-less speed variation.

Partial Introduction

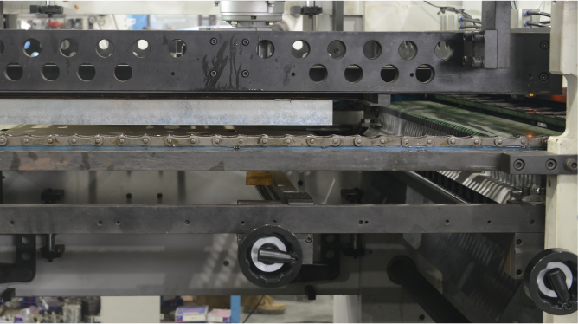

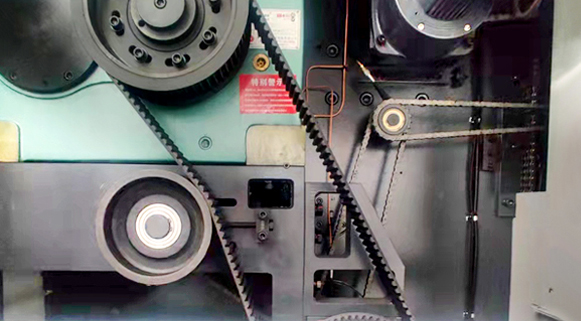

Taiwan high precision intermittent segmentation ensure high positional precision for long time usage.

● MHC1300/1500 series adopt timing belt driven system

● MHC1650 series adopt chain driven system

Adopt concentrated auto lubrication system to make sure the driven parts working better.

Configurations

| Feeding Unit | MHC-1100BLC/1300BLC/1500BLC/1650BLC |

| 01. Procedure feeding section | 〇 |

| 02. With monitoring video device, you can see the operation of the paper receiving section | 〇 |

| 03. 10.4 inch color screen shows the working state of the machine | 〇 |

| 04. With pre-code paper stacking mechanism, high efficiency | 〇 |

| 05. Electromechanical double detector | 〇 |

| 06. Import paper conveyor belt and stainless steel conveyor plate | 〇 |

| 07. Pneumatic lifting device for feeding frame | 〇 |

| 08. Adjustable rubber wheels and brush wheels ensure accurate positioning of front gauge and side return | 〇 |

| 09. After the secondary positioning, the paper die-cutting precision can be guaranteed | 〇 |

| 10. Fish scale paper feeding, smooth and accurate | 〇 |

| 11. Side gauge, front gauge paper photoelectric detection | 〇 |

| 12. Push-pull side gauge, one set for operation side and one set for transmission side. Side gauges can be adjusted between push and pull gauges to meet different paper requirements | 〇 |

| Die-cutting Unit | |

| 01. Nodular cast iron main body and left and right wall panels and upper platform, lower platform (MHC-1100BLC) | 〇 |

| 02. The main body of ductile iron, upper platform and lower moving platform (MHC-1300BLC/1500BLC/1650BLC) | 〇 |

| 03. Imported worm gear, worm with 40CR crankshaft | 〇 |

| 04. Rotary device for die cutting bottom plate and cutter template | 〇 |

| 05. Electric pressure regulating device can realize accurate pressure control through PLC touch screen keys | 〇 |

| 06. The whole set of imported anodized aluminum alloy tooth row and positioning structure 7 groups, each tooth row adopts adjustable tooth row structure | 〇 |

| 07. Import main drive chain | 〇 |

| 08. Imported intermittent divider | 〇 |

| 09. Imported synchronous belt, belt wheel drive (MHC-1100BLC) | 〇 |

| 10. Main drive inlet pneumatic clutch brake device | 〇 |

| 11. Japanese SMC pressure detection device, pressure is too low alarm | 〇 |

| 12. Die-cut plate frame adopts center line fast positioning device structure (MHC-1100BLC) | 〇 |

| 13. The connection between the die cutting plate and the die cutting plate frame adopts the form of grasping snail mother and screws, and the central positioning system is used when loading, which is fast and accurate (MHC-1300BLC/1500BLC/1650BLC) | 〇 |

| 14. Die-cut plate frame and die-cut bottom plate are locked by Japanese SMC gas regulator, to avoid the upper plate frame lock installation is not in place, effectively avoid the loss caused by human factors operation | 〇 |

| 15. The whole machine adopts centralized automatic oil supply system to ensure that the transmission part is not short of oil | 〇 |

| 16. Equipped with air storage tank to ensure the stable air pressure (MHC-1100BLC) | 〇 |

| Stripping Unit | |

| 01. Clean up the waste transmission mechanism (MHC-1100BLC) | 〇 |

| 02. You can choose whether to use the waste cleaning function (MHC-1100BLC) | 〇 |

| 03. Drive mechanism of waste – removing mould in the middle (MHC-1100BLC) | 〇 |

| 04. Clean the waste transmission mechanism (MHC-1100BLC) | 〇 |

| 05. Adopt upper and lower double frame waste cleaning mechanism (MHC-1300BLC/1500BLC/1650BLC) | 〇 |

| 06. Adopt male and female models to achieve all kinds of waste (MHC-1300BLC/1500BLC/1650BLC) | 〇 |

| 07. The installation of the middle waste cleaning board adopts the center line quick positioning installation mode, so that the operator can quickly install the waste cleaning board and improve the efficiency of changing the board | 〇 |

| Delivery Unit | |

| 01. Adjustable mechanical paper receiving brush and paper pressing mechanism to help the teeth discharge paper and stack (MHC-1100BLC) | 〇 |

| 02. Paper collecting and paper leveling device | 〇 |

| 03. Photoelectric detection of the upper and lower limit switch prevents the paper from being piled too high and the paper from being rolled up | 〇 |

| 04. Plug rod type auxiliary paper receiving frame, can realize non-stop machine paper receiving (MHC-1100BLC) | 〇 |

| 05. Paper receiving bidirectional auxiliary blowing, manual sampling mechanism, easy to operate (MHC-1100BLC) | 〇 |

| 06. Manual sampling mechanism, easy to operate (MHC-1300BLC/1500BLC/1650BLC) | 〇 |

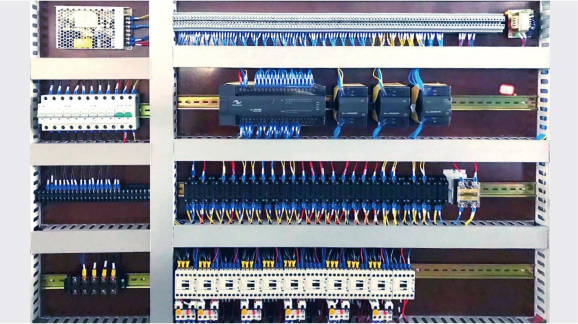

| Electrical Parts | |

| 01. Huichuan PLC control system | 〇 |

| 02. The die-cutting part adopts 10.4 – inch touch screen | 〇 |

| 03. All the machines adopt relays, AC contactors, air switches and buttons made by Moeller from Germany to ensure the stability and reliability of electrical parts | 〇 |

| 04. The whole machine adopts Japanese Omron photoelectric switch, optical fiber, encoder and sensor, to ensure the accuracy and stability of electrical detection of each part of the action | 〇 |

Note: This allocation sheet is for reference only, the formal allocation sheet is subject to the contract. Standard configuration: 〇; Optional: △

Main Technical Parameter

| Model | MHC-1100BLC | MHC-1300BLC | MHC-1500BLC | MHC-1650BLC |

| Max. Paper Size | 1100×790mm | 1290×940mm | 1500×1100mm | 1650×1200mm |

| Min. Paper Size | 400×350mm | 470×420mm | 470×420mm | 550×500mm |

| Max. Die-cutting Size | 1070×770mm | 1280×920mm | 1480×1080mm | 1620×1180mm |

| Max. Working Speed | 7000s/h | 5000s/h | 5000s/h | 4000s/h |

| Main Motor Wattage | 11kw | 11kw | 15kw | 15kw |

| Max. Working Pressure | 300T | 300T | 300T | 300T |

| Machine Weight | 15T | 17T | 19T | 22T |

| Overall Dimension | 8600×4200×2350mm (L: paper prepared track included, W: platform included) | 9300×4400×2300mm (L: paper prepared track included, W: platform included) | 9840×4600×2300mm (L: paper prepared track included, W: platform included) | 10100×5000×2500mm (L: paper prepared track included, W: platform included) |

| Scope Of Application | ≤7mm corrugated paper, E, B, C, A and AB corrugated paper | ≤8.5mm corrugated paper, E, B, C, A and AB corrugated paper | ≤8.5mm corrugated paper, E, B, C, A and AB corrugated paper | ≤8.5mm corrugated paper, E, B, C, A and AB corrugated paper |

Drawing