Dayuan : Innovation at CHINA PRINT 2025

We are excited to announce that Dayuan will be attending CHINA PRINT 2025! The exhibition will take place in Beijing from May 15th to 19th, 2025.

Our booth is located at W2-007.

CHINA PRINT 2025, a premier international printing exhibition of global scale and scope, has drawn significant attention from the printing industry worldwide. As a pioneer in the printing and packaging industry, Dayuan views this event not merely as a stage to unveil technological advancements, but also as a pivotal platform for fostering industry-wide dialogue and strategic collaboration. We are presenting six globally leading hot stamping, die-cutting, and sheet cutting machines, with live demonstrations of packaging solutions for cigarette packs, liquor boxes, dairy cartons, and more.

- MHK-3S920TTT TRIOPRESS Automatic High Speed Triple Hot Stamping & Die Cutting Machine:

Deeply customized for the cigarette packaging industry, MHK-3S920TTT achieves holographic hot stamping, multi-layer hot stamping, deep embossing, and various complex processes in a single pass. Featuring independently developed hot stamping control systems and foil feeding systems, it delivers a maximum speed of up to 6,200 sheets per hour. Even at high-speed operation, it ensures precision machining and consistent quality for every cigarette pack.

- MHK-2S1050RMC DUOPRESS Automatic High Speed Die Cutting Machine with Heating System:

MHK-2S1050RMC performs multiple complex processes in a single pass with a maximum speed of 7,200 sheets/hour. Each unit is servo-driven, allowing flexible process combinations—operate the entire production line or select individual units as needed. The PLC touchscreen control panel ensures intuitive operation and precise adjustments. Featuring a micro-adjustable plate frame and cutting plate, the system enables rapid and accurate setup, significantly reducing plate change over time while maintaining high-speed precision and production efficiency.

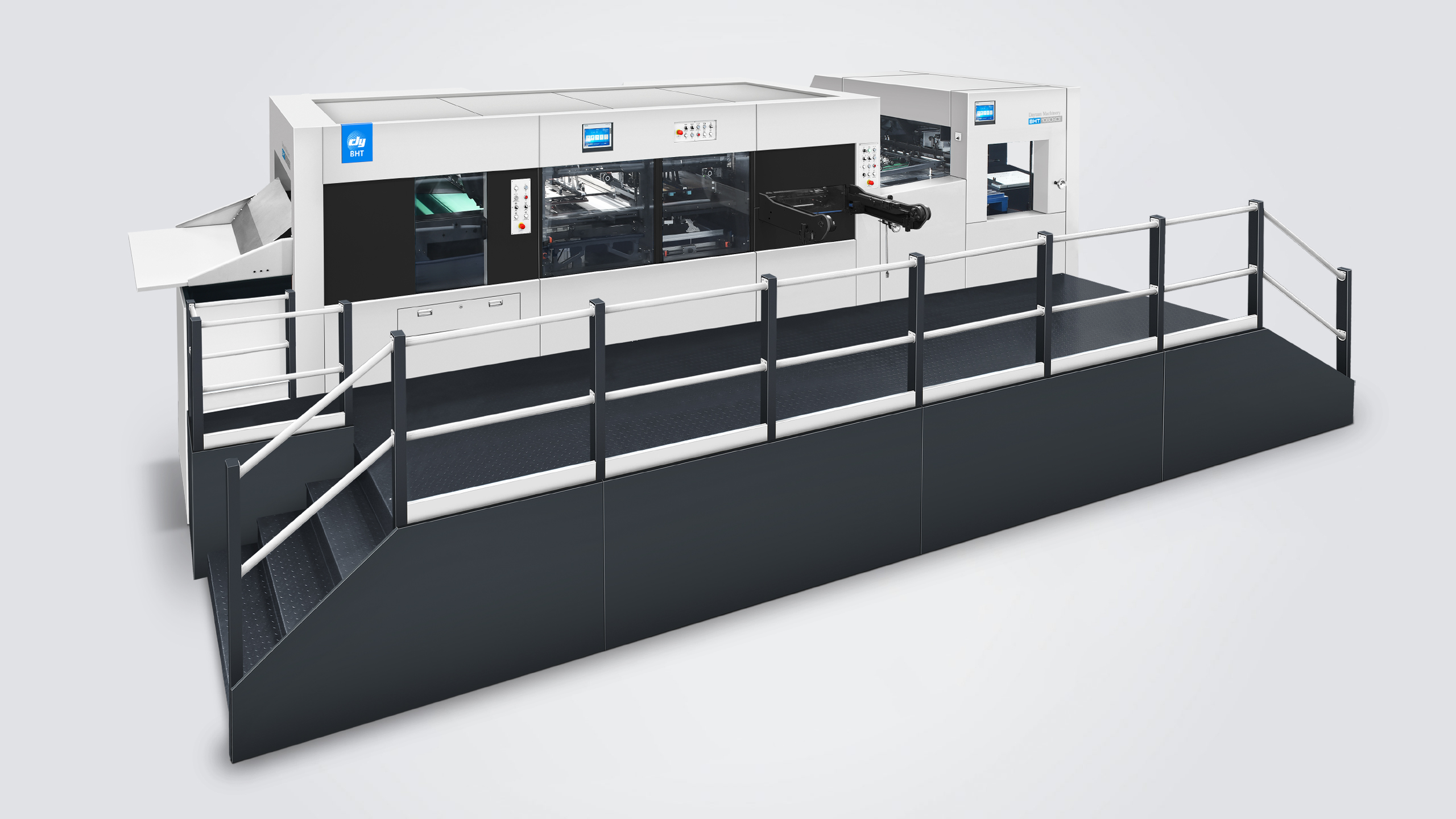

- BHT-1060SCE Automatic Die Cutting And Creasing Machine With Stripping & Blanking :

Maximum Speed 8000 sheets/hour. BHT-1060SCE integrates die-cutting, waste stripping, and blanking(product separation) in one paper feed, reducing manual intervention in post-processing and enhancing production efficiency. Turbo-variable transmission technology in die-cutting unit ensures precise dynamic platform movement.

- MHK-1500AT Automatic Hot Foil Stamping & Die Cutting Machine(Heavy Duty):

MHK-1500AT is designed for large-format foil stamping & deep embossing applications with heavy-duty 600-ton press capacity and maximum speed 600 sheets/h. Advanced technology like self-developed foil stamping control system, precision servo-controlled gripper rear positioning system and automatic lubrication supply/cooling system significantly boosts output while ensuring quality.

- MHK-1180CE Automatic Stripping Die Cutting & Creasing Machine:

MHK-1180CE is designed for high-efficiency die-cutting & waste stripping for milk cartons, luxury handbags & premium packaging. It can achieve non-stop paper collecting with roll-up type auxiliary take-up stand.

Max speed: 7,000 sheets/hour

Stock Range: 100-2000g/m²cardboard, 0.1-2mm cardboard, ≤4mm corrugated board.

- SMC-1500ZH Servo Precision Double Helix High Speed Sheet Cutter Machine With Auto Splicer & Auto Pallet Changer:

With one-touch start, the machine achieves automatic centralized alignment of all parts, enabling features such as non-stop paper splicing, automatic reverse bending, edge correction, longitudinal cutting, slitting, paper collection, and non-stop tray changing. It reaches a maximum speed of 540 cuts per minute and utilizes vacuum adsorption for paper transport, ensuring no scratches or impact marks on the paper surface—delivering exceptional product quality for users

We warmly welcome all buyers to engage with us and share your innovative ideas during the use of our equipment. During the exhibition, our team will conduct live demonstrations to showcase the outstanding performance of our machines through real-time operation. We look forward to direct communication with customers, offering more personalized solutions to drive the printing and packaging industry’s transition from traditional manufacturing to smart manufacturing—achieving a dual leap in both production efficiency and product quality.